Unlocking Performance: Why Reach Trucks Dominate Narrow Aisle Warehousing

Reach trucks, also known as forward-moving forklifts, are widely used in high-density warehouses, distribution centers, and cold storage facilities. Their unique design—with an extendable mast that “reaches” forward—makes them ideal for narrow aisles and vertical racking systems. Key advantages include:

- Exceptional maneuverability in tight spaces

- Higher lift heights compared to standard counterbalance forklifts

- Lower overall footprint, increasing warehouse storage density

- Energy-efficient operation with electric drive systems

These features make reach trucks a staple in logistics operations requiring speed, precision, and space optimization.

Leading Global Reach Truck Brands and Popular Models

When considering a battery upgrade or replacement, it's important to understand the most widely used reach truck brands and models. The following manufacturers dominate the global market:

| Brand | Popular Reach Truck Models |

|---|---|

| Toyota | 8FBR, 7FBR, BT Reflex series |

| Jungheinrich | ETV 112/114/216, ETV C16-C20 |

| Crown | ESR 5200 series, RM/RMD 6000 series |

| Hyster | R1.4-2.5, R2.0HD |

| Linde | R10-R20, Linde R14-R20G |

| Mitsubishi | RB14N2, RB16N2C |

| Nissan/UniCarriers | RG series, UFW series |

| Hangcha | CQD series, A series |

| HELI | CQD20, CQDH series |

These models typically operate with lead-acid batteries, but many are now being upgraded to lithium technologies for improved performance.

Why Upgrade to LFP Lithium Batteries for Reach Trucks?

Benefits Over Lead-Acid Batteries

| Feature | Lead-Acid Battery | LFP Lithium Battery |

|---|---|---|

| Charging Time | 8–10 hours | 2–3 hours (quick charge supported) |

| Maintenance | Regular watering, ventilation | Maintenance-free |

| Battery Life | ~1,200 cycles | 3,000–5,000 cycles |

| Energy Efficiency | 70–75% | 95%+ |

| Operational Downtime | Frequent battery changes | Opportunity charging enabled |

| Total Cost of Ownership | Higher | Lower over lifecycle |

Lithium iron phosphate (LFP) batteries are particularly well-suited for reach trucks due to their safety, high energy density, and stable discharge performance, even in cold storage environments.

Technical Guide: How to Replace and Upgrade Reach Truck Batteries

Upgrading from lead-acid to lithium requires proper planning and integration. Here's a step-by-step guide:

- Assess Compatibility Confirm your reach truck model supports lithium battery replacement. Most mainstream models listed above can be upgraded using drop-in replacement lithium packs.

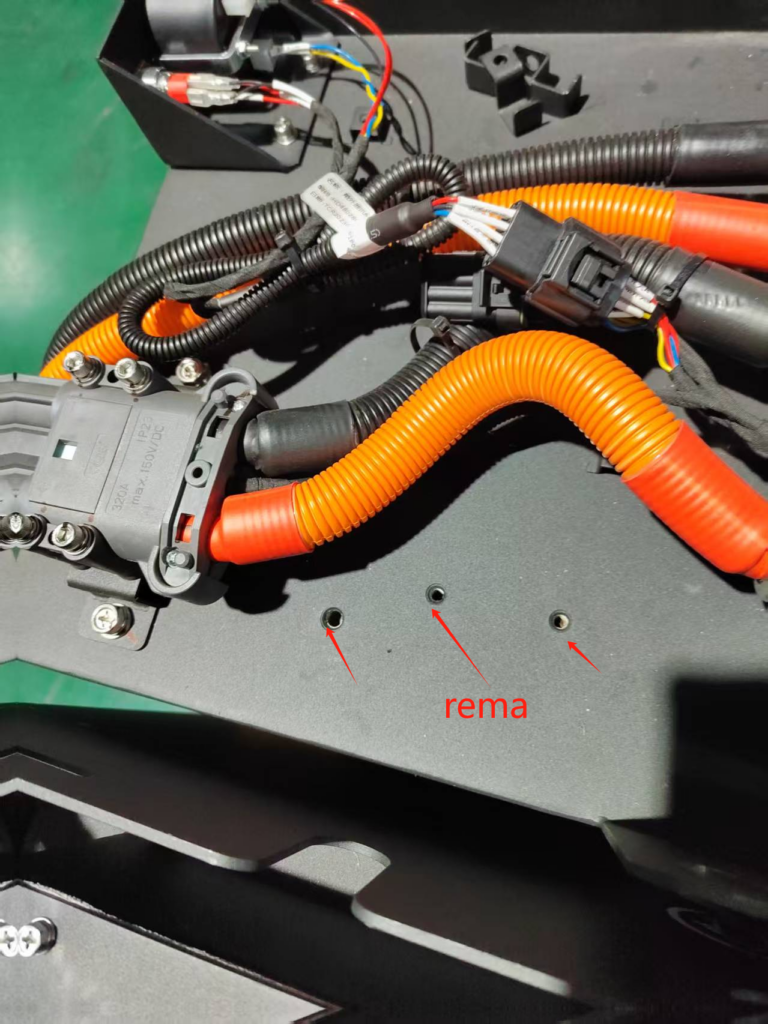

- Battery Specifications Matching Ensure voltage, dimensions, and connector types match the truck's original configuration. LFP batteries can often be customized.

- Remove Lead-Acid Battery Safely Disconnect the terminals, remove counterweights if required, and lift the battery using appropriate equipment.

- Install Lithium Battery Pack Position the new SPIDERWAY LFP lithium battery securely, connect terminals, and test voltage output.

- Configure the Battery Management System (BMS) Ensure the BMS integrates with the truck's onboard system. SPIDERWAY batteries come with smart BMS pre-integrated.

- Final Safety Checks Perform load tests, brake tests, and lift system function tests. Monitor battery status via the LCD or app interface.

- Train Operators Brief operators on the shorter charge time, opportunity charging, and absence of maintenance requirements.

Why Choose SPIDERWAY LFP Lithium Batteries for Reach Trucks?

SPIDERWAY is a leading manufacturer of LFP (LiFePO₄) lithium battery systems for industrial electric vehicles. We offer custom-built, smart battery packs designed specifically for reach truck applications.

Key Advantages of SPIDERWAY Reach Truck Batteries:

- Custom-fit designs for Toyota, Jungheinrich, Crown, Linde, and more

- Easy drop-in replacement with plug-and-play integration

- Global distribution & technical support

- Advanced BMS with real-time monitoring and CAN/RS485 compatibility

- Cold storage-compatible with intelligent thermal management

- Eco-friendly & maintenance-free

We have successfully upgraded thousands of electric reach trucks across Europe, North America, and Southeast Asia, helping fleet managers significantly reduce maintenance and energy costs while increasing uptime.

Frequently Asked Questions (FAQ)

Q1: Can I upgrade any reach truck to lithium batteries? Yes, most major brands and models can be upgraded. SPIDERWAY provides drop-in solutions for mainstream reach truck platforms.

Q2: Will switching to lithium affect my truck’s warranty? SPIDERWAY batteries are designed to be fully compatible. However, consult your manufacturer or dealer regarding warranty terms before upgrading.

Q3: How long does it take to charge a lithium battery for reach trucks? Typically, 2–3 hours with standard chargers. Fast chargers can reduce it to under 2 hours.

Q4: Are SPIDERWAY lithium batteries safe for cold storage? Absolutely. Our LFP batteries are equipped with insulation and heating options for low-temperature operations.

Q5: How long will a SPIDERWAY lithium battery last? Our LFP batteries are rated for over 3,500 charge cycles under normal operating conditions.

Conclusion

Upgrading your reach truck battery from lead-acid to lithium is not just a trend—it’s a smart investment. With improved energy efficiency, reduced downtime, and long-term cost savings, lithium technology is revolutionizing warehouse operations worldwide.

SPIDERWAY stands at the forefront of this transformation, offering high-performance LFP lithium battery solutions tailored for global reach truck fleets. Contact us today to explore customized upgrade plans and unlock the full potential of your material handling equipment.

https://www.spider-way.com/reach-truck-battery-replacement-and-upgrade-guide/?_unique_id=692c608e1b2cf

Comments

Post a Comment