The electrification of heavy-duty trucks, particularly in the freight and logistics sector, has become one of the most significant developments in the transportation industry. As global pressure increases to reduce carbon emissions and adopt more sustainable solutions, electric trucks (ETs) are quickly gaining traction. With advancements in lithium-ion battery technology, electric trucks are becoming more viable, offering a promising alternative to traditional diesel-powered trucks. This article explores the growing trend of electric trucks, the benefits and challenges they present, and the essential role lithium batteries play in powering these vehicles.

The Shift Towards Electric Trucks: The shift towards electric trucks is not just a passing trend—it's a global movement. Governments and companies are increasingly adopting policies that promote the transition from internal combustion engine (ICE) trucks to electric alternatives. This shift is driven by multiple factors, including stricter emissions regulations, rising fuel costs, and the growing demand for sustainable transportation solutions.

According to recent data, the electric truck market is expected to experience significant growth. MarketsandMarkets forecasts that the global electric truck market size will grow from USD 1.8 billion in 2022 to USD 18.2 billion by 2030, with a compound annual growth rate (CAGR) of 34.4% during the forecast period. This growth is driven by increasing investments in electric truck technology, advancements in lithium battery systems, and expanding charging infrastructure.

Advantages of Electric Trucks:

- Lower Operating Costs: One of the primary advantages of electric trucks over diesel-powered trucks is their lower operating costs. Electric trucks have fewer moving parts, which translates to less maintenance and fewer breakdowns. Additionally, the cost of electricity to charge an electric truck is significantly lower than the cost of diesel fuel. Over the vehicle's lifetime, the savings in fuel and maintenance costs can be substantial.

- Environmental Impact: Electric trucks have a significantly lower carbon footprint compared to diesel trucks. With zero tailpipe emissions, they help reduce air pollution and contribute to the reduction of greenhouse gases (GHGs). As companies and governments around the world implement stricter emission standards, the environmental benefits of electric trucks become more appealing.

- Government Incentives: Many governments are offering tax incentives, grants, and subsidies to encourage the adoption of electric trucks. In the United States, for instance, the Environmental Protection Agency (EPA) offers incentives to fleets that purchase electric vehicles. These incentives help offset the higher upfront cost of electric trucks, making them a more attractive option for businesses.

- Improved Performance: Electric trucks offer impressive torque and acceleration capabilities, providing a smoother and more efficient driving experience. This is particularly beneficial for heavy-duty trucks that require high levels of power and responsiveness for hauling freight across long distances.

Challenges of Electric Trucks:

- High Initial Costs: The initial cost of purchasing an electric truck is still relatively high, mainly due to the cost of lithium-ion batteries. However, as technology advances and economies of scale are realized, these costs are expected to decrease over time. Additionally, government incentives and lower operating costs help make electric trucks more financially viable.

- Limited Range: One of the main challenges faced by electric trucks is their limited range compared to diesel trucks. While advancements in battery technology are continually improving energy density, long-haul electric trucks still face challenges related to range limitations. For example, the typical range of an electric truck can vary between 150 and 300 miles on a single charge, which may not be sufficient for some applications without frequent recharging.

- Charging Infrastructure: A key challenge for the widespread adoption of electric trucks is the availability of reliable and fast charging infrastructure. Charging stations need to be strategically placed along major freight routes, and charging times need to be reduced for electric trucks to compete with diesel trucks in terms of operational efficiency.

Cost Comparison: Electric Trucks vs. Diesel Trucks:

- Fuel Costs: Electric trucks are far more cost-effective in terms of fuel consumption. While diesel trucks consume around 6 to 8 miles per gallon, electric trucks can travel the same distance for a fraction of the energy cost. According to a study by the International Council on Clean Transportation (ICCT), the cost of operating an electric truck can be 50% to 70% lower than a diesel truck, depending on local energy prices.

- Maintenance Costs: Electric trucks also have lower maintenance costs due to fewer moving parts. Diesel engines require regular maintenance such as oil changes, exhaust system repairs, and transmission work. In contrast, electric trucks only require routine tire checks and battery maintenance.

- Initial Purchase Price: While the initial purchase price of electric trucks is higher, it is offset by lower operating and maintenance costs over the truck’s lifecycle. Furthermore, the continued reduction in battery prices and increasing government support is making electric trucks more affordable.

Lithium Battery Solutions Behind Electric Trucks: The backbone of any electric vehicle, including trucks, is its battery. Lithium-ion batteries, particularly Lithium Iron Phosphate (LiFePO4) batteries, are rapidly becoming the standard for heavy-duty electric trucks. LiFePO4 batteries offer several distinct advantages, including:

- Longer Cycle Life: LiFePO4 batteries have a longer lifespan compared to other lithium-ion chemistries, making them ideal for heavy-duty trucks that require long-term performance. With a cycle life of up to 5,000 cycles or more, LiFePO4 batteries ensure that electric trucks can operate for many years before requiring a battery replacement.

- Enhanced Safety: LiFePO4 batteries are known for their inherent safety, with a lower risk of thermal runaway compared to other lithium chemistries. This makes them a safer choice for heavy-duty electric trucks that may operate in demanding environments.

- Fast Charging and Efficiency: LiFePO4 batteries charge more quickly and offer higher efficiency compared to traditional lead-acid batteries, reducing downtime and allowing trucks to get back on the road faster.

- Environmental Benefits: As a non-toxic, environmentally friendly solution, LiFePO4 batteries align with the sustainability goals of electric truck manufacturers and their customers.

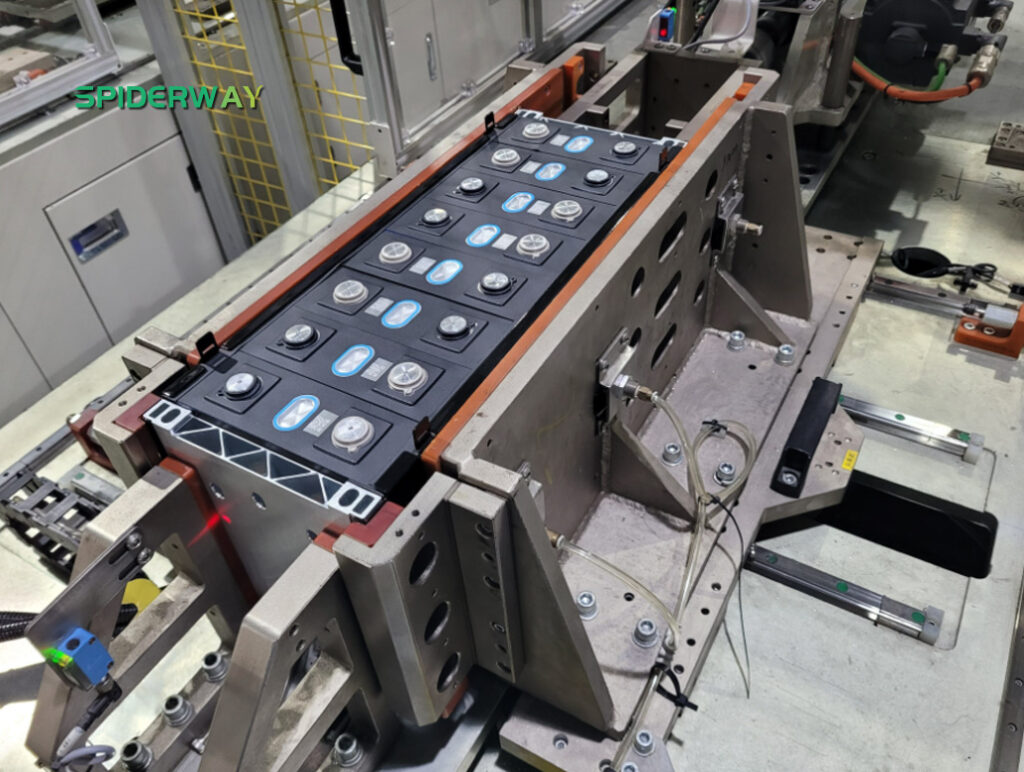

SPIDERWAY LFP Heavy-Duty Electric Truck Power Solutions: SPIDERWAY offers advanced LFP (Lithium Iron Phosphate) battery solutions designed specifically for heavy-duty electric trucks. Our high-performance, durable, and safe LFP batteries provide the ideal power solution for fleets looking to transition to electric vehicles. With a long lifecycle, fast charging times, and a reduced environmental impact, SPIDERWAY LFP batteries are the future of heavy-duty truck electrification.

Explore our range of LiFePO4 electric truck batteries at SPIDERWAY LFP.

Conclusion: The transition to electric trucks is gaining momentum, driven by technological advancements, cost savings, and the global push for sustainability. While there are still challenges to overcome, such as high initial costs and limited range, the benefits of electric trucks—lower operating costs, improved environmental impact, and enhanced performance—are undeniable. With the continued development of lithium-ion battery solutions like LiFePO4, the future of heavy-duty truck electrification looks brighter than ever. SPIDERWAY is proud to be at the forefront of this transformation, offering reliable, efficient, and safe power solutions for the next generation of electric trucks.

https://www.spider-way.com/the-trend-of-electrification-in-heavy-duty-trucks-and-the-lithium-battery-solutions-behind-it/?_unique_id=67e5f95996538

Comments

Post a Comment