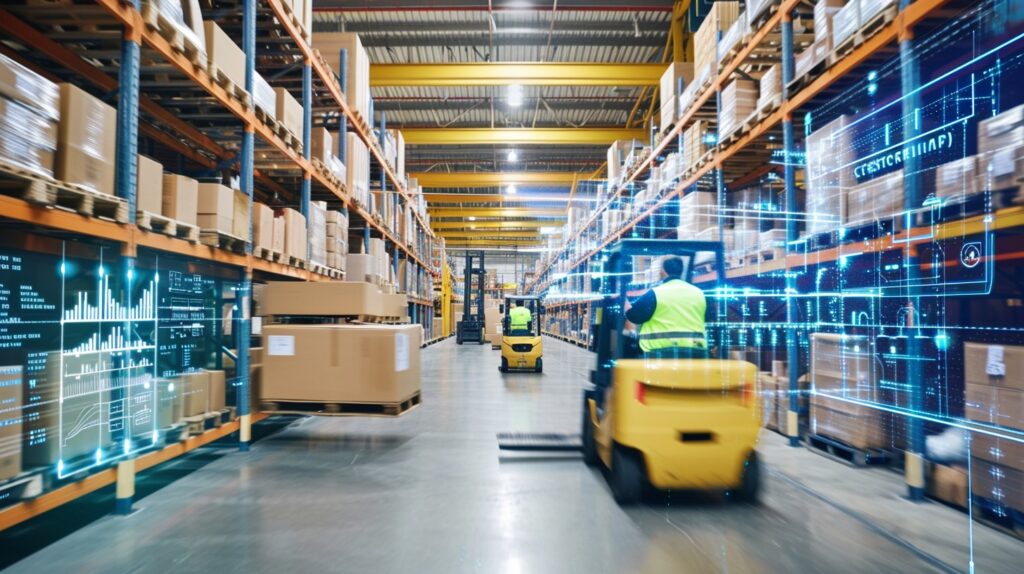

In the rapidly evolving landscape of logistics and supply chain management, modern warehouses face increasing demands for efficiency, speed, and adaptability. To meet these challenges, the integration of advanced technologies, particularly in material handling, has become essential. Automated systems such as Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are at the forefront of this transformation, offering numerous benefits:

- Enhanced Efficiency and Productivity: Automation streamlines repetitive tasks like sorting, picking, and transporting goods, ensuring a continuous workflow, minimizing downtime, and increasing throughput.

- Improved Accuracy: Automated equipment performs tasks with high precision, reducing errors in order fulfillment and inventory management compared to manual labor.

- Increased Safety: By handling physically demanding or hazardous tasks, automation reduces the risk of workplace injuries, promoting a safer environment for employees.

- Labor Optimization: Automation alleviates labor shortages by decreasing reliance on manual work, allowing staff to focus on more strategic, value-added activities.

- Cost Efficiency: Although initial investments in automation can be significant, long-term savings are realized through reduced labor costs, decreased downtime, and optimized resource utilization, leading to a favorable return on investment.

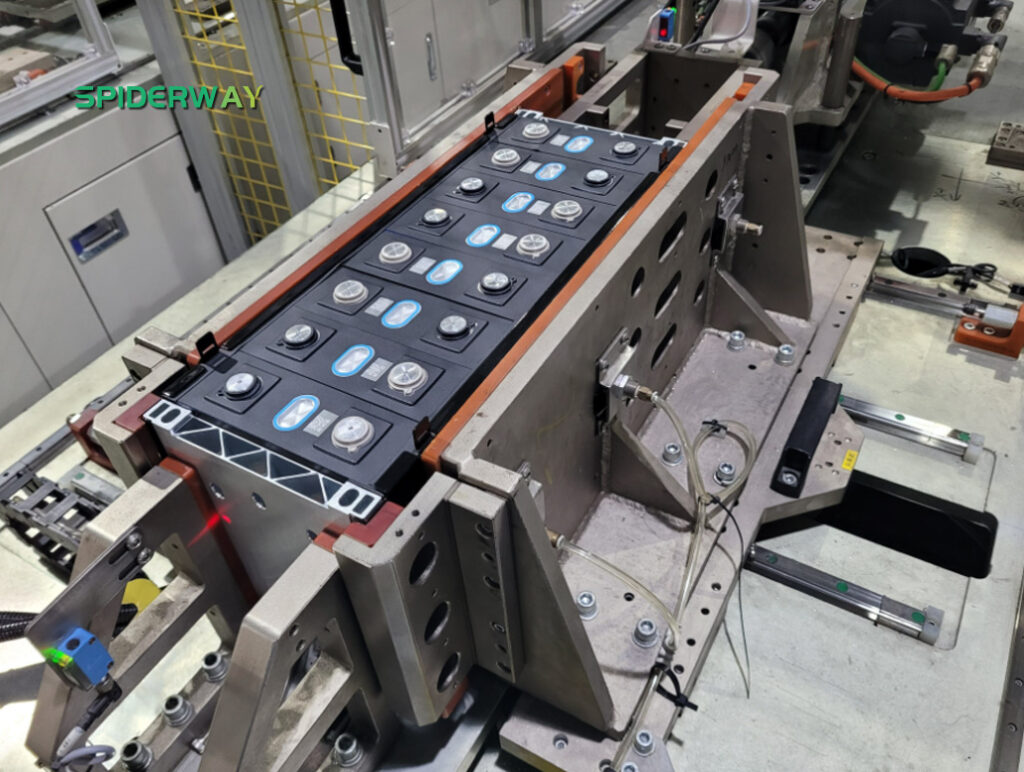

Central to the effectiveness of these automated systems is their power source. Lithium-ion batteries have emerged as the preferred choice for powering AMRs, AGVs, and other industrial robots due to their superior performance characteristics:

- Higher Energy Density: Lithium-ion batteries provide longer run times, enabling equipment to operate for extended periods without frequent recharging.

- Rapid Charging: These batteries can be charged much faster than traditional lead-acid batteries, often during short breaks, thereby minimizing equipment downtime.

- Extended Lifespan: With a longer cycle life, lithium-ion batteries reduce the frequency of replacements, contributing to lower maintenance costs.

- Lightweight Design: The reduced weight of lithium-ion batteries enhances the agility and efficiency of automated equipment, especially in space-constrained warehouse environments.

- Minimal Maintenance: Unlike lead-acid batteries, lithium-ion batteries require little to no maintenance, eliminating the need for regular water top-ups and associated labor.

- Advanced Battery Management Systems (BMS): Integrated BMS provide real-time monitoring and safety features, ensuring optimal performance and protection against potential issues.

By adopting lithium-ion battery-powered automation, warehouses can achieve significant improvements in operational efficiency, accuracy, safety, and cost savings. This strategic move positions businesses to remain competitive and responsive in the dynamic landscape of modern warehousing.

For more information on how SPIDERWAY's lithium-ion battery solutions can empower your warehouse automation initiatives, please visit www.spider-way.com.

https://www.spider-way.com/how-lithium-ion-batteries-are-driving-the-smart-revolution-in-warehousing/?_unique_id=67e6df0654eb4

Comments

Post a Comment