Graphene Lithium Battery Development Progress: Key Features, Comparisons with Other Battery Technologies, and Future Outlook for Industrial Vehicles

What Are Graphene Lithium Batteries?

Graphene lithium batteries are a next-generation battery technology that integrates graphene—one of the most conductive and durable materials known—with traditional lithium-ion technology. Graphene enhances the conductivity of the battery, allowing for faster electron flow and quicker charging times compared to conventional lithium-ion batteries. These batteries offer several key advantages:

- Improved Energy Density: Graphene’s high conductivity and large surface area allow for more efficient energy storage, resulting in higher energy density.

- Faster Charging: With graphene's enhanced conductivity, graphene lithium batteries can charge much faster than traditional lithium-ion batteries.

- Longer Lifespan: Graphene-based batteries are more resistant to wear and tear, reducing degradation over time.

- Higher Thermal Conductivity: The improved heat dissipation capabilities reduce the risk of overheating, thus enhancing battery safety.

While graphene lithium batteries are still in the research and development stage, the progress in this field shows great promise for a wide range of applications, particularly in electric vehicles and renewable energy storage.

Comparing Graphene Lithium Batteries with Other Battery Technologies

When comparing graphene lithium batteries to other types of lithium-ion batteries, several key differences emerge in terms of performance, cost, and application suitability:

1. Graphene Lithium Batteries vs. LFP (Lithium Iron Phosphate) Batteries

LFP batteries, commonly used in electric vehicles (EVs) and industrial vehicles, are known for their excellent thermal stability, long lifespan, and superior safety. However, they have lower energy density compared to newer technologies. Graphene lithium batteries, on the other hand, offer enhanced energy density and faster charging times, making them ideal for applications that require quick energy replenishment. However, LFP batteries have a proven track record in safety and cost-effectiveness.

- Key Advantages of LFP: Safety, stability, longevity.

- Key Advantages of Graphene: Faster charging, higher energy density.

2. Graphene Lithium Batteries vs. NCM (Nickel Cobalt Manganese) Batteries

NCM batteries, widely used in consumer electronics and electric vehicles, have a higher energy density than LFP but at a higher cost. The use of rare metals like cobalt and nickel makes NCM batteries expensive and less sustainable. In contrast, graphene lithium batteries offer a more environmentally friendly alternative, as graphene is a more abundant material. Although NCM batteries have higher energy density than LFP batteries, graphene batteries can potentially surpass NCM in energy storage capacity while providing a more sustainable and cost-effective solution.

- Key Advantages of NCM: Higher energy density, longer range for EVs.

- Key Advantages of Graphene: Lower cost, better sustainability, faster charging.

3. Graphene Lithium Batteries vs. Sodium-Ion Batteries

Sodium-ion batteries are considered a potential alternative to lithium-based batteries due to the abundance of sodium. However, they have a lower energy density compared to both lithium-ion and graphene batteries. Graphene lithium batteries outperform sodium-ion batteries in terms of energy storage and charge/discharge rates, although sodium-ion batteries are gaining traction due to their cost-effectiveness and environmental benefits.

- Key Advantages of Sodium-Ion: Lower cost, abundant raw materials.

- Key Advantages of Graphene: Higher energy density, faster charging.

Future Trends and Industrial Vehicle Applications

Graphene lithium batteries are expected to play a significant role in the future of electric vehicles, particularly for industrial applications. Their high energy density and fast charging capabilities make them suitable for large-scale industrial machinery, including forklifts, material handling equipment, and other industrial vehicles.

As the demand for electric industrial vehicles grows, the graphene battery is poised to offer the performance enhancements needed for industries that rely on heavy-duty, high-performance equipment. These batteries will help reduce downtime, increase efficiency, and lower the total cost of ownership for businesses.

Potential Benefits for Industrial Vehicles

- Longer Operational Hours: Graphene lithium batteries' fast charging and high capacity will allow industrial vehicles to operate for extended periods without frequent recharging.

- Reduced Charging Time: Faster charging can reduce downtime, a critical factor in industries where productivity is key.

- Increased Safety and Durability: Graphene's thermal conductivity will help maintain optimal operating temperatures, minimizing the risks of overheating or fire.

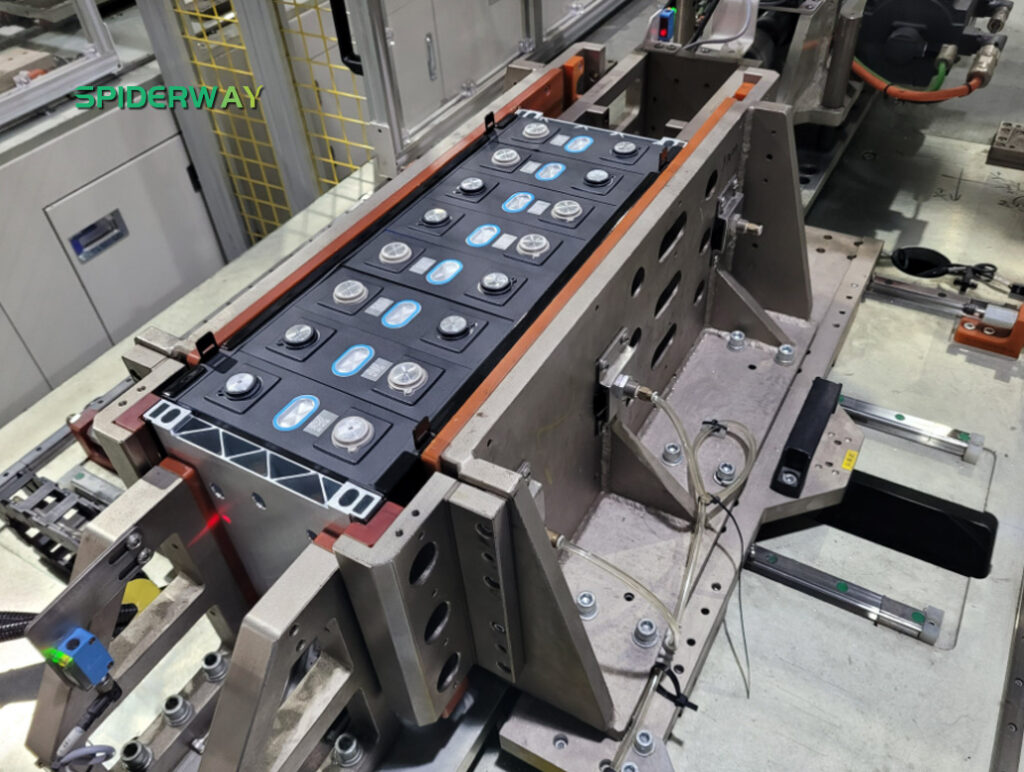

Advantages of SPIDERWAY LFP Industrial Vehicle Batteries

While graphene lithium batteries are still under development, SPIDERWAY LFP batteries are already proving to be a superior choice for industrial vehicles, particularly in demanding applications. SPIDERWAY LFP (Lithium Iron Phosphate) batteries are known for their safety, stability, and durability, which are essential features in industrial environments.

Key Benefits of SPIDERWAY LFP Batteries:

- Safety: SPIDERWAY LFP batteries offer the highest level of safety, with minimal risk of thermal runaway or fire, making them ideal for heavy-duty industrial applications.

- Stability: LFP batteries maintain stable performance across a wide temperature range and under various load conditions.

- Durability: These batteries have a long lifespan, with fewer charging cycles required compared to other battery technologies, which translates to lower maintenance costs.

- Maturity: LFP technology is well-established and proven in industrial applications, making SPIDERWAY LFP a reliable and cost-effective solution for modern industries.

As graphene lithium batteries continue to evolve, they promise significant advancements in energy storage, charging efficiency, and overall performance. While the technology is still in its developmental phase, the potential for graphene-based batteries to surpass traditional lithium-ion batteries is evident. However, for industries that require reliable, safe, and cost-effective solutions today, SPIDERWAY LFP industrial vehicle batteries remain a top choice due to their proven safety, stability, durability, and maturity. For businesses seeking to stay ahead in the rapidly growing industrial vehicle sector, adopting LFP battery technology now is a smart move for both performance and sustainability.

https://www.spider-way.com/graphene-lithium-battery-development-progress-key-features-comparisons-with-other-battery-technologies-and-future-outlook-for-industrial-vehicles/?_unique_id=67e4769b8dd3f

Comments

Post a Comment