The industrial forklift market has traditionally been dominated by diesel and other internal combustion engine (ICE) forklifts. However, a rising interest in environmentally friendly, cost-effective, and high-performance alternatives has led to the increasing adoption of lithium-ion battery technology, specifically LiFePO4 (Lithium Iron Phosphate) batteries, to replace diesel powertrains in forklifts. This article explores the feasibility, benefits, cost comparison, and market trends surrounding the conversion of diesel-powered forklifts to lithium battery systems, with a special focus on SPIDERWAY's LFP forklift battery products, which offer cutting-edge solutions for forklift battery conversions.

Feasibility of Diesel Forklift to LiFePO4 Battery Conversion

The conversion of diesel forklifts to LiFePO4 lithium batteries involves replacing the traditional internal combustion engine with a high-capacity lithium battery pack, along with the associated electrical components such as controllers and charging systems. This solution is viable due to the advanced technology and robust performance characteristics of LiFePO4 batteries, which are known for their safety, long cycle life, and ability to handle high power demands in industrial settings.

The conversion process typically requires professional expertise to ensure compatibility between the new battery system and the forklift’s operational requirements. However, modern systems are designed to be modular and adaptable, making it easier to convert a wide range of diesel forklifts to electric power.

Market Size and Growth Potential

The market for lithium battery conversions in forklifts is experiencing significant growth, driven by several key factors:

- Environmental Regulations: With growing environmental concerns and stricter emissions regulations in many regions, industries are increasingly seeking alternatives to diesel-powered equipment. LiFePO4 batteries are a cleaner, greener solution that helps businesses comply with environmental standards.

- Cost of Fuel: The rising costs of diesel fuel are prompting companies to explore more economical solutions. Lithium batteries have a lower operational cost compared to diesel, as they require less maintenance and have significantly lower energy costs over time.

- Battery Technology Advancements: Improvements in battery life, charging speed, and energy density have made lithium batteries a more attractive option for material handling equipment. This has significantly reduced the barriers to adopting lithium-powered forklifts, even for businesses with existing diesel fleets.

As companies continue to focus on sustainability and operational efficiency, the market for LiFePO4-powered forklifts is set to expand rapidly. The global forklift market is expected to witness a substantial increase in the adoption of electric forklifts, with LiFePO4 conversions playing a pivotal role in this transition.

Benefits of Converting Diesel Forklifts to LiFePO4 Batteries

- Environmental Sustainability: One of the primary benefits of converting diesel forklifts to LiFePO4 batteries is the reduction in carbon emissions. Diesel-powered forklifts contribute significantly to air pollution, whereas electric forklifts with lithium batteries produce zero emissions during operation, helping to improve air quality and reduce a company's carbon footprint.

- Lower Operating Costs: LiFePO4 batteries are more energy-efficient and cost-effective in the long run. They require fewer maintenance interventions compared to diesel engines, which can reduce downtime and maintenance costs. Additionally, the cost of electricity is often lower than diesel, making it a more affordable energy source for forklift operations.

- Increased Productivity: LiFePO4 batteries offer fast charging times and longer operational periods between charges compared to traditional lead-acid batteries. This enhances overall productivity by reducing downtime for recharging and allowing for more consistent operations throughout the day.

- Longer Battery Life: LiFePO4 batteries have a significantly longer lifespan compared to traditional lead-acid batteries. This translates into lower replacement costs and less frequent maintenance, which is particularly beneficial for businesses with large fleets of forklifts.

- Quieter Operation: Diesel forklifts are noisy, which can lead to an uncomfortable work environment. LiFePO4-powered forklifts are much quieter, contributing to a safer and more pleasant working environment for employees.

Cost Comparison: Diesel vs. Lithium Forklifts

While the initial investment for converting a diesel forklift to a lithium-powered one may be higher, the long-term savings far outweigh the upfront costs. Here’s a quick comparison:

- Fuel Costs: Diesel fuel is subject to price fluctuations and often costs more than electricity. Lithium-powered forklifts are cheaper to operate since electricity is generally more affordable and predictable in cost.

- Maintenance: Diesel engines require regular maintenance, including fuel system repairs, exhaust system maintenance, and engine-related issues. Lithium batteries, on the other hand, require minimal maintenance, primarily involving the battery and charging system.

- Battery Life and Replacement: Diesel forklifts require engine replacements and related parts over time. Lithium batteries, particularly LiFePO4, have a longer cycle life and can last up to 10 years or more, reducing the frequency of replacements.

While the upfront cost of conversion may seem significant, the savings on fuel, maintenance, and longer operational life make LiFePO4 conversions a highly cost-effective choice over time.

SPIDERWAY: Leading the Way in Lithium Battery Forklift Solutions

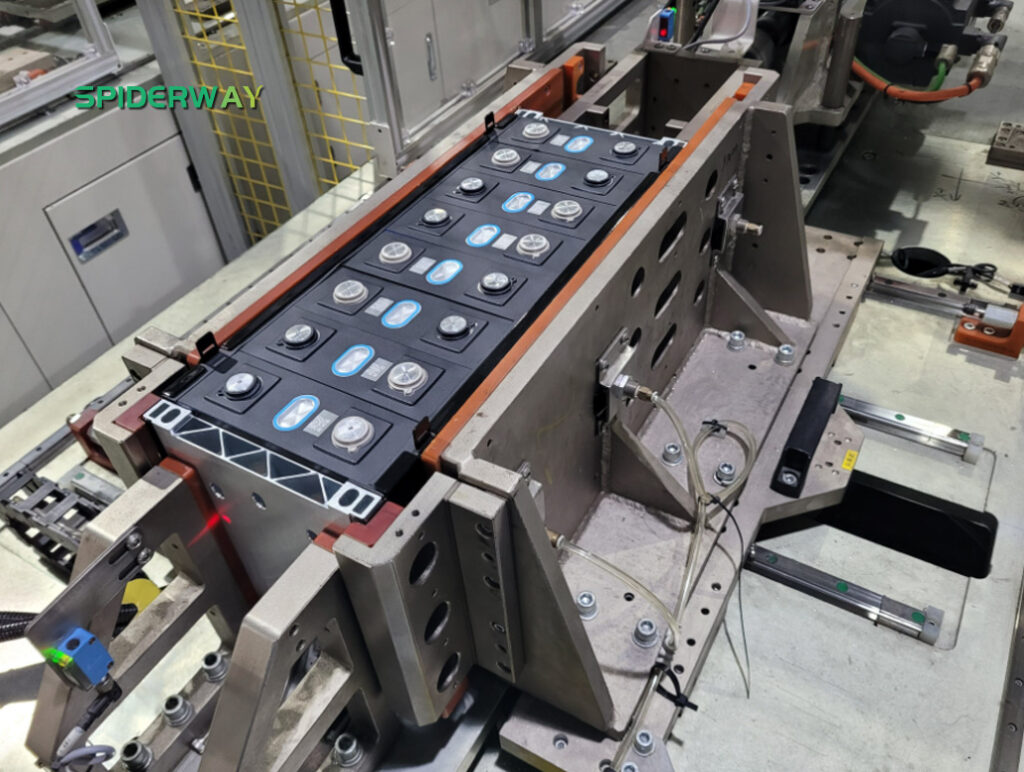

SPIDERWAY is a prominent supplier of LiFePO4 lithium forklift battery solutions, offering a range of high-performance products tailored for forklift applications. In addition to providing diesel-to-lithium conversion kits, SPIDERWAY also offers OEM solutions for upgrading lead-acid battery-powered forklifts to lithium battery systems.

Why Choose SPIDERWAY LFP Forklift Batteries?

- Superior Technology: SPIDERWAY’s LFP batteries are designed with advanced safety features, enhanced efficiency, and longer life cycles, ensuring reliable performance in industrial settings.

- Customization: SPIDERWAY offers flexible OEM solutions to suit various forklift models, providing businesses with tailored solutions that maximize compatibility and performance.

- Comprehensive Support: From the initial conversion process to ongoing maintenance, SPIDERWAY provides expert guidance and technical support to ensure seamless integration and optimal operation of lithium-powered forklifts.

- Sustainability: By choosing SPIDERWAY’s lithium battery solutions, companies contribute to a cleaner environment and lower their carbon footprint, aligning with global sustainability goals.

Conclusion

Converting diesel forklifts to LiFePO4 lithium batteries is not only a feasible and sustainable solution but also a cost-effective one in the long term. With benefits such as reduced emissions, lower operating costs, and increased productivity, it’s no wonder that more businesses are making the switch to electric forklifts. SPIDERWAY’s advanced lithium forklift battery solutions provide an excellent option for companies looking to upgrade their existing fleets, whether they are transitioning from diesel or lead-acid batteries.

If you’re looking to modernize your forklift fleet, reduce costs, and improve your environmental impact, consider SPIDERWAY’s LiFePO4 forklift battery solutions today.

https://www.spider-way.com/diesel-forklift-to-lithium-battery-conversion-solution-lifepo4-power-benefits-and-feasibility/?_unique_id=67e5497cce6e4

Comments

Post a Comment