Converting diesel-powered internal combustion forklifts to LiFePO4 lithium battery technology is a game-changer for businesses aiming to achieve higher efficiency, reduced emissions, and lower operating costs. This guide from SPIDERWAY outlines the essential steps and components required to complete the conversion process successfully.

Key Considerations for Forklift Conversion

Before starting the diesel-to-LiFePO4 conversion, it is essential to gather accurate details about the forklift’s specifications and usage patterns:

- Determine Forklift Tonnage: Understanding the current engine-powered forklift’s tonnage is critical for matching the appropriate hydraulic pump and traction motor.

- Evaluate Work Hours: Assess the forklift’s daily operational hours to select a suitable lithium battery capacity and compatible charger.

Components Included in SPIDERWAY’s Solution

Our diesel forklift to LiFePO4 battery conversion package includes all the necessary components for a seamless upgrade:

- Two Controllers: One for traction motor control and one for pump control.

- Two Motors:

- Traction motor for vehicle movement.

- Hydraulic pump motor for lifting operations.

- One LiFePO4 Battery Pack:

- Includes communication features for real-time monitoring and diagnostics.

- One Charger: Optimized for the selected battery pack.

- One Wiring Harness: Ensures safe and efficient electrical connectivity.

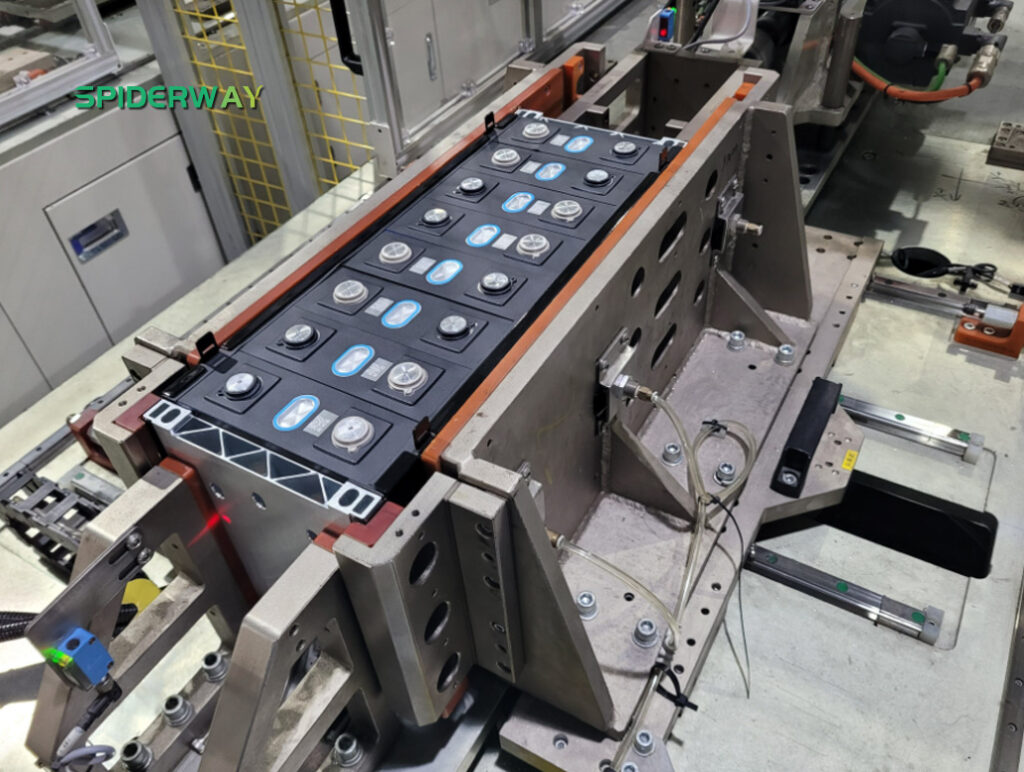

- Dashboard Instrumentation: For battery status and system control.

- Accelerator Pedal: Designed for smooth operation.

Step-by-Step Conversion Process

- Inspect and Document Existing Setup: Record the forklift’s specifications, including engine size, hydraulic system requirements, and usage patterns.

- Select the Right Components: Match the motor and pump sizes to the forklift’s tonnage and operational needs.

- Install Motors and Controllers: Replace the diesel engine with the electric traction motor and hydraulic pump motor. Connect these to their respective controllers.

- Integrate the LiFePO4 Battery Pack: Secure the battery in a dedicated compartment, ensuring proper ventilation and access for maintenance.

- Wire the System: Use the wiring harness to connect all components, including the controllers, battery, and dashboard instruments.

- Test and Optimize: Power up the system, perform functionality tests, and fine-tune the settings for optimal performance.

Why Choose SPIDERWAY for Forklift Conversion?

SPIDERWAY specializes in providing tailored diesel forklift conversion solutions that prioritize performance, durability, and sustainability. Here are the key advantages of our products and services:

- High-Performance Components: Our LiFePO4 battery packs deliver long-lasting power with rapid charging capabilities.

- Customizable Solutions: We design conversion kits to match the specific needs of your forklift model and usage requirements.

- Expert Support: From initial assessment to post-installation optimization, our technical team ensures a smooth transition.

- Cost Savings: Reduced fuel expenses, lower maintenance costs, and extended battery lifespan offer significant operational savings.

Conclusion

Upgrading diesel forklifts to LiFePO4 battery power not only enhances productivity but also aligns with modern environmental and operational standards. With SPIDERWAY’s comprehensive conversion kits, your business can transition to a more sustainable and cost-effective future.

For more information about SPIDERWAY’s forklift conversion solutions, visit our website or contact us today to discuss your specific needs.

https://www.spider-way.com/diesel-forklift-conversion-to-lifepo4-battery-power-technical-guide/?_unique_id=67e549823d03b

Comments

Post a Comment