Battery Management Systems (BMS) are integral to the operation and safety of lithium-ion batteries, especially in applications such as forklifts where performance and reliability are paramount. Here's a detailed explanation of what BMS is and its importance in the context of lithium batteries:

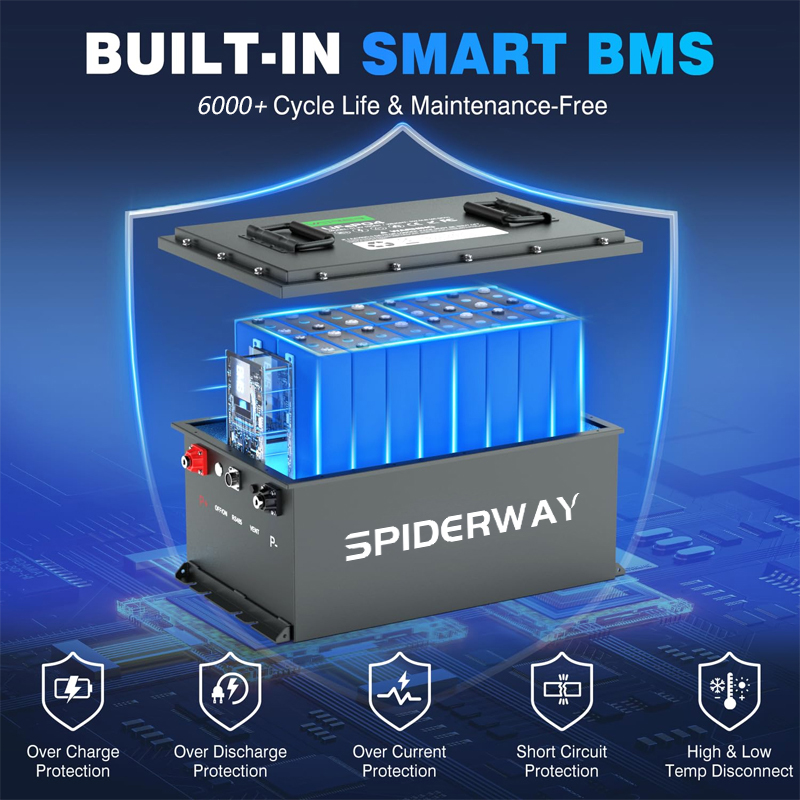

What is a BMS? A Battery Management System (BMS) is an electronic system designed to monitor, control, and protect rechargeable battery cells or battery packs. In the case of lithium-ion batteries, which are commonly used in electric vehicles, energy storage systems, and various industrial applications, a BMS plays a critical role in ensuring the safe and efficient operation of the battery pack.

Key Functions of BMS:

- Voltage Monitoring: BMS measures the voltage of each cell in a battery pack to ensure they are all within the safe operating range. This helps prevent overvoltage, which can lead to cell damage or failure.

- Current Management: It tracks the current flowing in and out of the battery, which is essential for estimating the State of Charge (SOC) and preventing over-discharge or over-charge of the cells.

- Temperature Control: BMS monitors the temperature of the battery cells to prevent overheating, which can be a safety hazard and degrade battery life.

- Cell Balancing: One of the most important functions of a BMS is to balance the charge across all cells in a battery pack. This is achieved through either passive or active balancing techniques to ensure uniform capacity and extend the overall life of the battery.

- Safety Protection: BMS incorporates various safety features such as over-voltage, under-voltage, over-temperature, and short-circuit protection to prevent potential hazards.

- Communication: BMS communicates with the vehicle or device it is powering, as well as with the charger, to ensure optimal charging and discharging cycles.

Importance in Lithium-ion Batteries: Lithium-ion batteries are known for their high energy density and long cycle life, but they require precise management to maintain these benefits. The BMS is responsible for optimizing the performance of lithium-ion batteries by:

- Enhancing safety through constant monitoring and protection mechanisms.

- Prolonging battery life by preventing overcharge and over-discharge.

- Maximizing the runtime and efficiency of the battery pack through intelligent charge and discharge strategies.

- Facilitating real-time data exchange between the battery, the charging station, and the host vehicle or equipment, which is crucial for forklift operations where uptime is critical.

Advancements and Innovations: With the growing demand for reliable and efficient energy storage, BMS technology continues to evolve. Innovations in BMS include more sophisticated algorithms for SOC estimation, advanced cell balancing techniques, integration with telematics for remote monitoring, and the use of multi-CAN communication for enhanced system integration.

In summary, a BMS is an essential component of any lithium-ion battery system, providing the necessary intelligence to ensure safety, reliability, and optimal performance. As the adoption of lithium-ion batteries expands across various industries, the role of BMS in managing these batteries becomes increasingly significant.

https://www.spider-way.com/what-is-bmsbattery-management-systems%ef%bc%9f/?_unique_id=6736081412222

Comments

Post a Comment