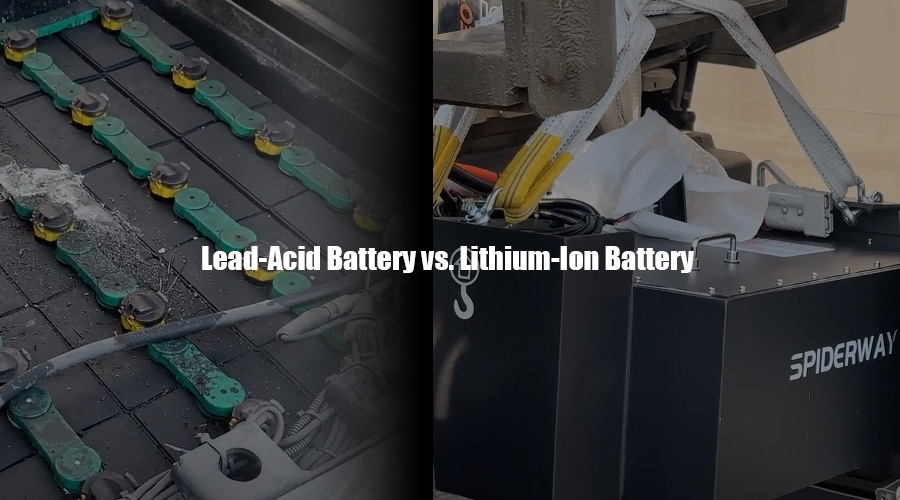

In the fast-evolving industrial battery market, many companies face a critical choice between lithium-ion and lead-acid batteries when powering their forklifts. With significant differences in performance, cost-effectiveness, and maintenance requirements, it’s essential to understand the pros and cons of each battery type.

This article provides an in-depth comparison of lithium-ion and lead-acid forklift batteries, examining the key advantages, disadvantages, and data-driven insights for each. This guide will also share a real-world case study where a South Korean company upgraded its aging Doosan and Toyota forklifts from lead-acid to SPIDERWAY lithium-ion batteries, highlighting the exceptional benefits and product features of SPIDERWAY’s solutions.

Key Differences Between Lithium-Ion and Lead-Acid Forklift Batteries

| Feature | Lithium-Ion Battery | Lead-Acid Battery |

|---|---|---|

| Energy Density | High | Moderate |

| Charge Time | 1-2 hours | 8-12 hours |

| Battery Life Cycle | 3,000-5,000 cycles | 500-1,000 cycles |

| Maintenance Requirements | Low (No water refills needed) | High (Regular water refills) |

| Environmental Impact | Lower (recyclable, less toxic) | Higher (toxic lead, disposal issues) |

| Weight | Lightweight | Heavy |

| Cost Efficiency Over Time | High | Moderate |

1. Energy Density and Efficiency

- Lithium-Ion Batteries offer a higher energy density, providing more power output per kilogram. This feature not only enables longer operation times but also reduces the frequency of battery changes, increasing productivity.

- Lead-Acid Batteries have lower energy density, often requiring frequent recharging or replacement during extended work shifts. As a result, businesses relying on lead-acid batteries may face downtime and reduced productivity.

2. Charging Time and Efficiency

- Lithium-Ion: Typically recharges in 1-2 hours, offering minimal downtime and enabling “opportunity charging” during breaks.

- Lead-Acid: Charging lead-acid batteries can take between 8-12 hours, requiring forklifts to be out of service for prolonged periods. This limitation can be costly in 24/7 operations where equipment downtime impacts workflow.

3. Battery Lifespan

- Lithium-ion batteries generally have 3,000 to 5,000 charge cycles, significantly outlasting lead-acid batteries, which range between 500 and 1,000 cycles. This difference results in longer operational life for lithium-ion, which offsets their higher initial investment over time.

4. Maintenance Needs

- Lithium-Ion Batteries require virtually no maintenance. They eliminate the need for water refills, corrosion checks, and equalization charging, making them highly convenient for industries looking to reduce downtime and maintenance costs.

- Lead-Acid Batteries demand frequent attention, such as water level checks, terminal cleaning, and regular maintenance sessions, adding ongoing labor and time costs.

5. Environmental Impact

- Lithium-ion batteries are more environmentally friendly due to their recyclability and lower toxicity. Lead-acid batteries contain lead, a hazardous material, creating more challenges in terms of safe disposal.

6. Cost Efficiency

- While lithium-ion batteries come at a higher upfront cost, their lower maintenance, longer lifespan, and enhanced performance offer greater cost efficiency over time.

Real-World Case Study: South Korean Company Upgrades to SPIDERWAY Lithium-Ion Batteries

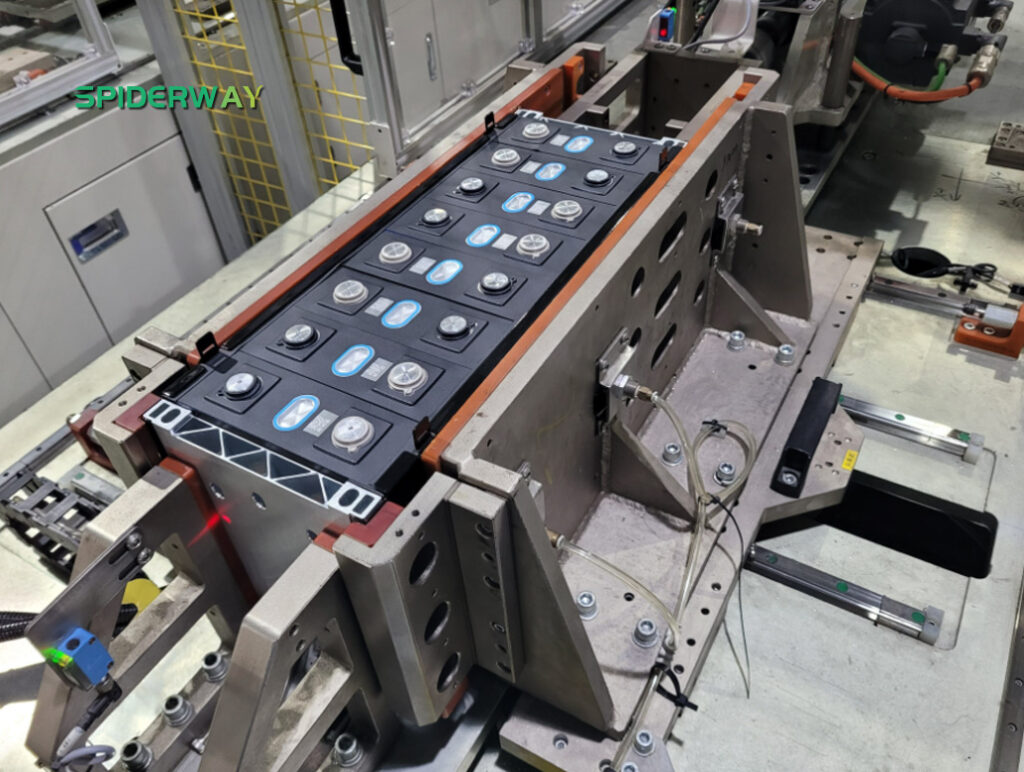

A prominent South Korean manufacturing firm recently upgraded its aging Doosan and Toyota forklift fleets from lead-acid to SPIDERWAY lithium-ion forklift batteries. This transition demonstrated notable improvements in productivity, battery life, and operational costs.

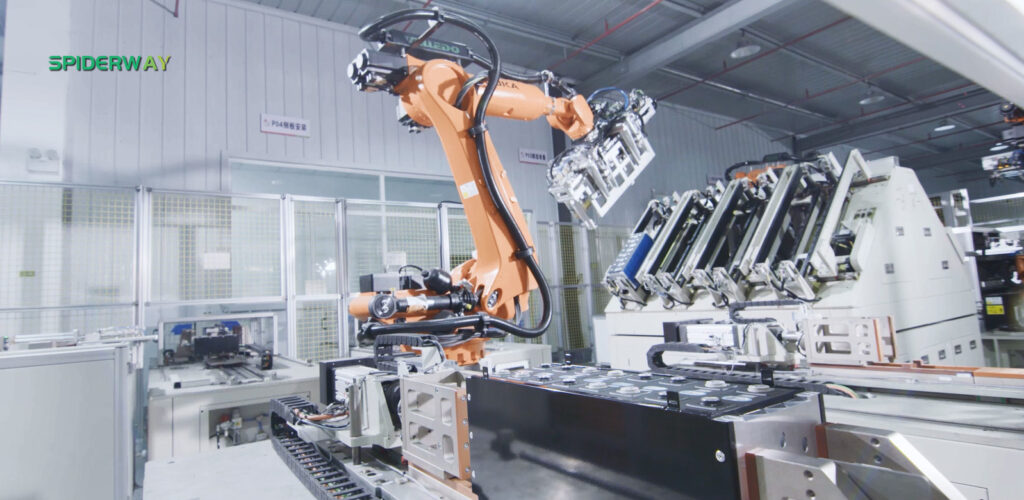

Why SPIDERWAY Lithium-Ion Forklift Batteries?

SPIDERWAY stands out in the lithium-ion battery industry due to its:

- Advanced Battery Management System (BMS): Enhances battery efficiency, monitors temperature, and optimizes performance, ensuring safety and extended battery life.

- Rapid Charging and High Energy Density: Minimizes downtime and maximizes operational hours.

- Longer Life Cycle and Reduced Maintenance: Reduces total ownership costs, a key consideration for large-scale operations.

- Proven Reliability: With a reputation for durability, SPIDERWAY lithium-ion batteries are ideal for heavy-duty forklift applications.

This successful upgrade has not only reduced maintenance and labor costs for the company but also significantly increased fleet productivity and decreased their overall environmental impact. By choosing SPIDERWAY lithium-ion forklift batteries, the company enhanced operational efficiency and sustainability while achieving substantial cost savings in the long run.

Why Choose Lithium-Ion Over Lead-Acid?

For industries looking to maximize efficiency, reduce downtime, and minimize long-term costs, the switch from lead-acid to lithium-ion forklift batteries is a strategic investment. SPIDERWAY’s lithium-ion forklift batteries offer an optimized solution, combining advanced technology, extended battery life, and sustainability advantages.

As the benefits of lithium-ion technology become clearer, more companies are expected to upgrade their forklift fleets, following the example of innovative firms that have already made the switch.

Content Keywords: lithium-ion forklift battery vs lead-acid, lithium-ion forklift battery, lead-acid replacement with lithium-ion forklift battery, forklift battery upgrade

https://www.spider-way.com/lithium-ion-forklift-battery-vs-lead-acid-battery-a-comprehensive-comparison/?_unique_id=6730214abd9f0

Comments

Post a Comment