This article explores the advantages of China’s OEM E-Bike lithium battery manufacturing industry, covering the unique characteristics of E-Bike lithium batteries, their differences from other vehicle power batteries, and current market trends.

Content Keywords: E-bike lithium battery factory, electric bicycle lithium battery supplier, electric bicycle lithium battery manufacturer.

The rapid growth of the electric bicycle (E-Bike) market has spurred significant demand for specialized lithium batteries, crucial for achieving optimal performance, durability, and efficiency in electric mobility. China, as a global manufacturing hub, has positioned itself as a leader in E-Bike lithium battery production, providing numerous Original Equipment Manufacturer (OEM) services for international brands. This article discusses the unique features of E-Bike lithium batteries, the distinctions between these and other power lithium batteries, and an analysis of China’s thriving E-Bike lithium battery OEM industry.

Key Characteristics of E-Bike Lithium Batteries

E-Bike lithium batteries differ from batteries used in electric vehicles (EVs) and other forms of transportation, primarily due to the power demands and size requirements of E-Bikes:

- Capacity and Power Output: E-Bike batteries generally range from 36V to 48V with capacities around 10Ah to 20Ah, offering enough power for typical E-Bike usage while remaining lightweight and compact.

- Weight Efficiency: Since weight is a critical factor for the performance and handling of E-Bikes, lithium batteries designed for these bikes are typically lighter and have a high energy density.

- Energy Density and Lifespan: These batteries often employ high-energy-density materials, such as lithium-ion, lithium-polymer, or LiFePO4 (Lithium Iron Phosphate), providing extended range and a longer lifecycle compared to traditional lead-acid batteries.

- Safety and Thermal Stability: As a priority for urban and outdoor environments, E-Bike batteries are often designed with enhanced safety features, such as protective casings and thermal management systems, to prevent overheating.

Differences Between E-Bike Lithium Batteries and Vehicle Power Lithium Batteries

While both E-Bike and EV batteries serve the purpose of providing energy, they are distinct in several ways:

- Power Requirements: EV batteries typically need to supply much higher power levels, often exceeding 300V, while E-Bike batteries remain within the 36V–48V range.

- Battery Size and Weight: E-Bike batteries are smaller and lighter than EV batteries, making them easier to manage and transport. This lightweight design is essential for riders who require a balance between range and mobility.

- Thermal Management Systems: Unlike EV batteries, which often require complex liquid cooling systems, E-Bike batteries are designed with simpler cooling methods due to their lower power requirements.

Overview of China’s E-Bike Lithium Battery OEM Industry

China's extensive manufacturing ecosystem, combined with advanced technology and cost advantages, has created a booming OEM industry for E-Bike lithium batteries. Many international brands partner with Chinese suppliers to leverage these advantages. Let’s explore the current state of the industry, supported by data.

- Market Growth and Demand: According to industry reports, the global E-Bike market is projected to grow at a CAGR of 12% through 2030, with lithium battery demand mirroring this growth. China is the largest supplier of E-Bike lithium batteries, contributing nearly 80% of the global supply.

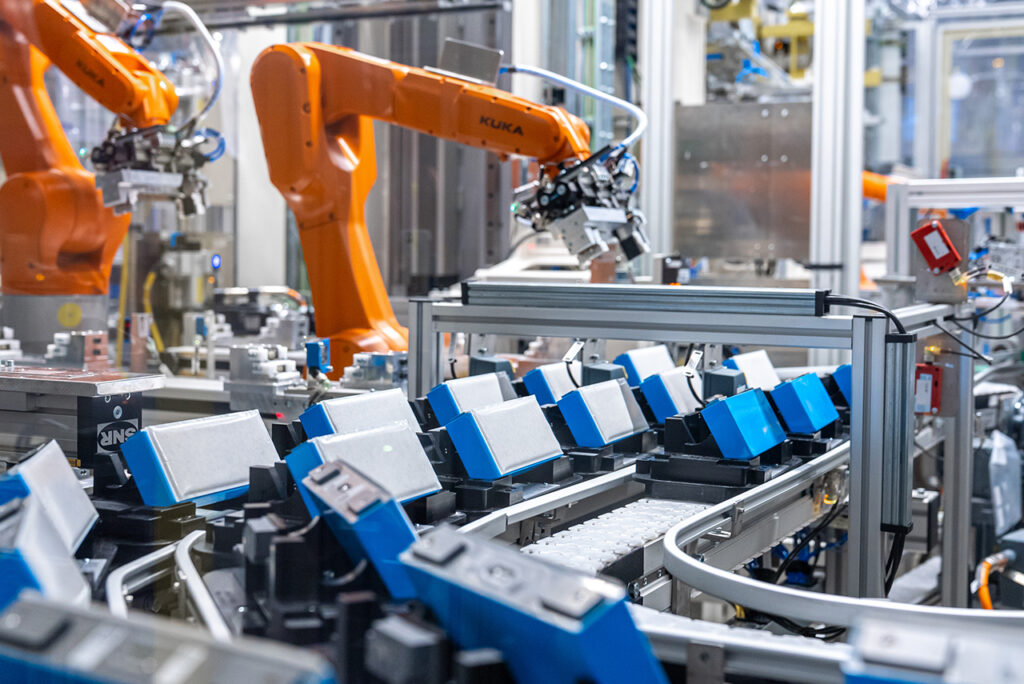

- OEM Production Capabilities: China’s E-Bike lithium battery factories are highly automated, utilizing advanced technology such as AI-driven quality control, robotics, and efficient production lines. This allows for high-volume output, ensuring reliable quality at scale.

- Cost and Efficiency Advantages: The cost of manufacturing E-Bike lithium batteries in China is typically lower due to economies of scale and a well-established supply chain for raw materials, such as lithium and cobalt. Chinese factories are also able to adjust to custom specifications quickly, providing tailored solutions for various E-Bike brands worldwide.

- Technological Innovation: China's E-Bike battery manufacturers continually invest in R&D, driving innovations such as improved battery lifespan, fast-charging capabilities, and integration with IoT for smart energy management. These advancements make Chinese OEMs attractive partners for brands seeking cutting-edge battery solutions.

- Sustainability Efforts: Responding to global environmental concerns, many Chinese manufacturers are adopting eco-friendly production practices, including recycling programs and energy-efficient processes, aligning with the values of environmentally-conscious brands.

Key Advantages of Partnering with Chinese E-Bike Lithium Battery Manufacturers

- Wide Range of Customization Options: Chinese E-Bike battery suppliers offer flexibility in customization, allowing brands to specify voltage, capacity, and casing materials according to their target market needs.

- Strong Supply Chain and Fast Turnaround: With access to a robust supply chain, Chinese manufacturers can quickly procure materials and respond to changes in demand, ensuring timely deliveries for international orders.

- High-Quality Standards: Many Chinese factories are certified with ISO and other international quality standards, ensuring that products meet rigorous safety and performance benchmarks, such as UL and CE certifications.

The Chinese OEM E-Bike lithium battery industry is a powerhouse in the global market, offering advanced manufacturing capabilities, customization options, and cost-effective production for international brands. With continued growth in the E-Bike market and increasing demand for efficient, reliable lithium batteries, Chinese manufacturers are well-positioned to support the needs of global E-Bike brands, helping them remain competitive while focusing on quality and innovation.

Content Summary: This article examined the unique features of E-Bike lithium batteries, compared them to other vehicle power batteries, and provided a comprehensive analysis of the advantages of sourcing E-Bike lithium batteries from China’s OEM industry. Key terms: E-bike lithium battery factory, electric bicycle lithium battery supplier, electric bicycle lithium battery manufacturer.

https://www.spider-way.com/chinas-e-bike-lithium-battery-manufacturing-an-analysis-of-oem-industry-advantages/?_unique_id=672b01d90e6c3

Comments

Post a Comment