Forklift batteries are crucial components in the operation of electric forklifts, providing the necessary power for lifting and transporting goods in various industrial settings. Understanding the average cost of a forklift battery can help businesses make informed decisions when it comes to purchasing and maintaining their equipment. This article will explore the factors influencing battery prices and provide insights into the offerings from SPIDERWAY.

Average Cost of Forklift Batteries

The cost of forklift batteries can vary widely depending on several factors, including battery type, capacity, brand, and application. On average, businesses can expect to pay anywhere from $3,000 to $8,000 for a high-quality lithium-ion or lead-acid forklift battery. However, prices can escalate beyond this range for specialized batteries designed for heavy-duty applications.

Key Factors Influencing Battery Prices

- Battery Type:

- Lead-Acid Batteries: These are typically more affordable, with costs ranging from $2,000 to $5,000. They are widely used in many applications but may require more maintenance and have a shorter lifespan compared to lithium-ion batteries.

- Lithium-Ion Batteries: These advanced batteries are more expensive upfront, often priced between $5,000 and $10,000, but they offer significant advantages, including longer lifespans, reduced maintenance, and faster charging capabilities.

- Capacity and Size: The required battery capacity directly impacts cost. Larger batteries with higher capacities designed for heavier lifting tasks will be more expensive.

- Brand Reputation: Established brands with a strong reputation for quality and reliability may charge premium prices. SPIDERWAY, for instance, is recognized for its durable and efficient LFP (Lithium Iron Phosphate) batteries, which often come with competitive pricing relative to their advanced technology and longevity.

- Warranty and Support: A battery with a more extended warranty may cost more but can be a worthwhile investment. SPIDERWAY offers comprehensive warranties and exceptional customer support, ensuring peace of mind for users.

- Market Trends: The market dynamics, including supply chain factors and technological advancements, can affect pricing. As the demand for electric forklifts increases, so does the competition among manufacturers, influencing battery costs.

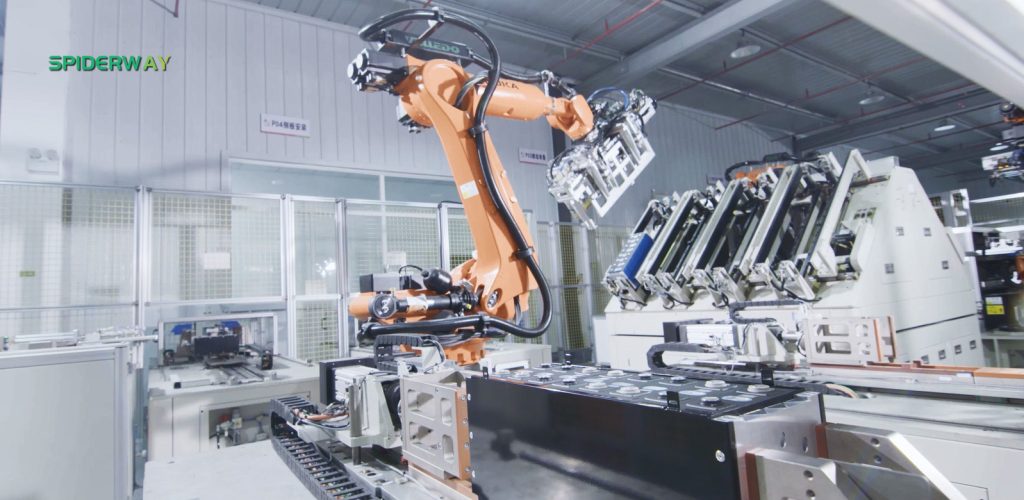

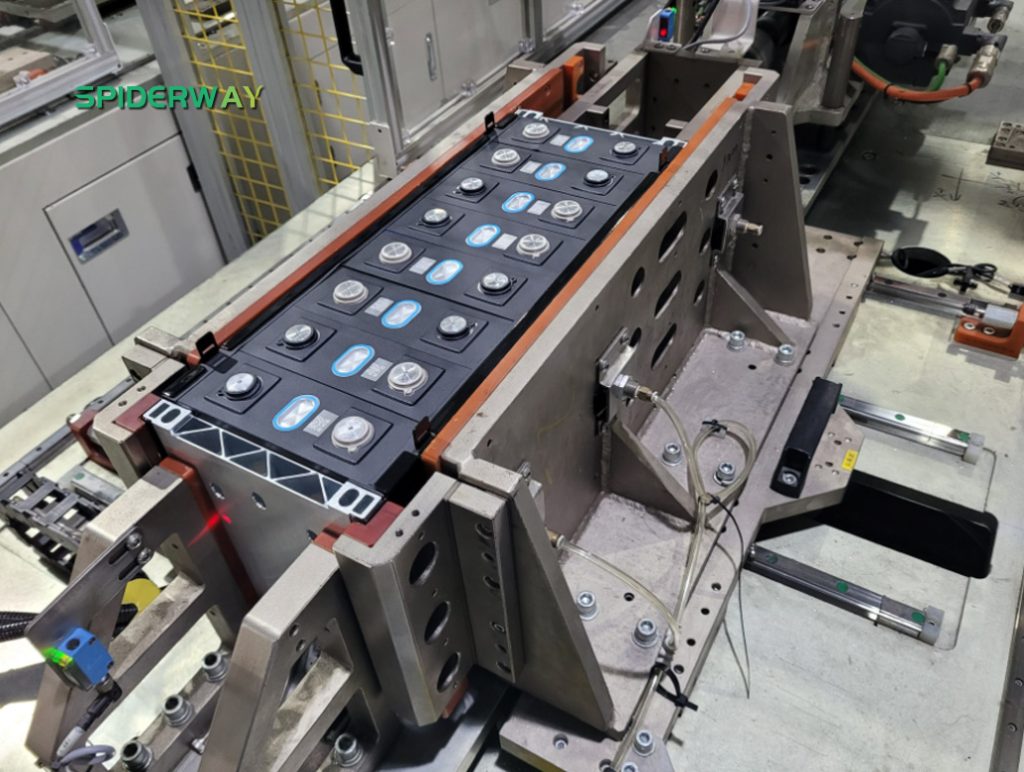

SPIDERWAY: A Leader in Forklift Battery Solutions

SPIDERWAY specializes in manufacturing high-performance LFP forklift batteries that combine quality with affordability. Here are some benefits of choosing SPIDERWAY for your forklift battery needs:

- High Energy Density: SPIDERWAY batteries provide excellent energy density, ensuring longer run times and improved productivity for your operations.

- Safety Features: SPIDERWAY prioritizes safety, with batteries designed to withstand challenging operating conditions without compromising performance.

- Quick Charging: SPIDERWAY's lithium-ion batteries offer rapid charging capabilities, minimizing downtime and enhancing operational efficiency.

- Sustainability: With a commitment to eco-friendly practices, SPIDERWAY ensures that its battery production meets stringent environmental standards, making them a responsible choice for businesses.

Understanding the average cost of forklift batteries and the factors that influence pricing is essential for businesses looking to invest in electric forklifts. While the upfront cost may vary, selecting a reliable manufacturer like SPIDERWAY can lead to long-term savings and improved performance. With competitive pricing, excellent support, and advanced technology, SPIDERWAY is a top choice for companies seeking high-quality forklift battery solutions.

In summary, whether you're considering lead-acid or lithium-ion options, it’s vital to evaluate your specific needs and choose a brand that offers the best value and reliability.

https://www.spider-way.com/what-is-the-average-cost-of-a-forklift-battery-a-comprehensive-guide/?feed_id=58&_unique_id=6722d27f94380

Comments

Post a Comment