As the demand for lithium batteries soars, especially for electric vehicles (EVs) and industrial applications, understanding the grading of lithium battery cells becomes increasingly important. Grading determines a cell’s quality, reliability, and, consequently, its suitability for different applications. This article delves into the specifics of lithium battery cell grading, with a particular focus on A-grade cells and LFP (Lithium Iron Phosphate) cells. We will explore the grading standards, price-performance distinctions, and showcase a comparison table of leading global cell manufacturers.

Lithium Battery Cell Grading: Definition and Standards

Lithium battery cells, including LFP cells, are graded based on their performance, capacity, cycle life, and overall quality. These grades directly influence their price and application:

- A-Grade Cells: These are the highest quality cells, characterized by top-tier performance metrics. They show minimal capacity deviation, consistent voltage levels, and minimal internal resistance variation. A-grade cells are typically used in premium applications such as electric vehicles and high-end industrial equipment due to their superior reliability.

- B-Grade Cells: These cells have slightly more deviations in capacity and performance and may show minor inconsistencies. B-grade cells are often used in applications where cost-efficiency is prioritized over long-term performance.

- C-Grade Cells and Below: Cells in these grades have noticeable deviations and may exhibit lower cycle life, making them suitable for low-cost, low-demand applications.

LFP (Lithium Iron Phosphate) Cell Grading Standards

LFP cells are favored for their safety, longer life cycles, and stable performance, especially in demanding environments. LFP cells undergo a stringent grading process, given their widespread use in EVs, industrial vehicles, and renewable energy storage.

- Performance Metrics: Grading typically assesses energy density, capacity retention, internal resistance, and thermal stability. A-grade LFP cells showcase the best metrics, which ensures longevity and reliability.

- Cost Implications: A-grade LFP cells are priced higher due to their quality and durability. The investment translates to longer cycle life and reliability, essential for critical applications like EVs and industrial machinery.

Performance and Pricing Comparison: A-Grade vs. Lower Grade Cells

| Parameter | A-Grade Cells | B-Grade Cells | C-Grade Cells |

|---|---|---|---|

| Capacity Deviation | Minimal (within ±1%) | Moderate (within ±5%) | Significant (±10% or more) |

| Voltage Consistency | Very stable | Slight variations | Unstable |

| Cycle Life | 3000-15,000 cycles (LFP cells) | 1000-2000 cycles | Less than 1000 cycles |

| Internal Resistance | Low and consistent | Moderate | High |

| Thermal Stability | Excellent (low overheating risk) | Average | Below average |

| Price Range | High-end pricing (20-50% more than lower grades) | Medium | Low |

Leading Global Lithium Battery Cell Manufacturers

Several companies have established themselves as the frontrunners in lithium battery cell manufacturing. These companies adhere to rigorous quality standards, ensuring their products meet the demands of various applications.

- CATL (Contemporary Amperex Technology Co. Limited): Known for its high-performance A-grade cells, CATL is a major supplier for the EV and energy storage industries.

- BYD: An industry leader in LFP and NMC (Nickel Manganese Cobalt) batteries, providing A-grade cells for EVs and consumer electronics.

- EVE Energy: Specializes in cylindrical and prismatic LFP cells, catering to both industrial and consumer markets.

- Lishen Battery: Known for reliable and high-quality cells, including A-grade LFP cells for high-demand applications.

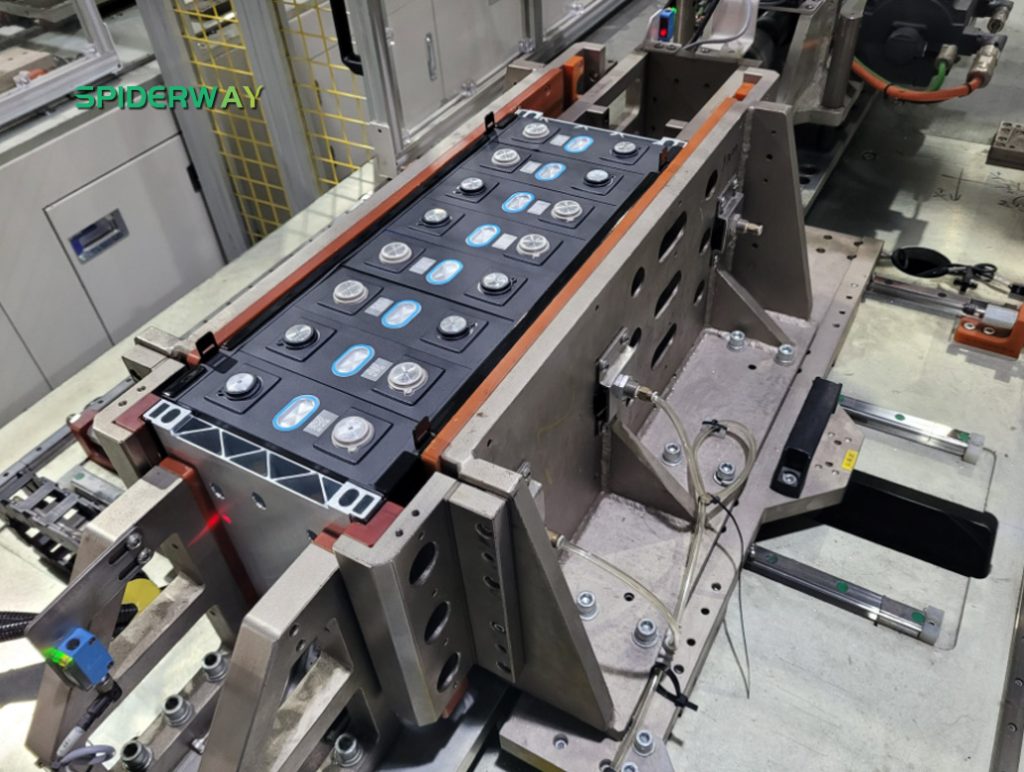

SpiderWay’s Commitment to Quality with A-Grade Cells

SpiderWay stands out in the industrial LFP battery market by exclusively utilizing A-grade cells from top manufacturers such as CATL, BYD, EVE, and Lishen. By sourcing only A-grade cells, SpiderWay ensures that each battery provides optimal performance, longevity, and safety. Some of the flagship SpiderWay products offer up to 15,000 charging cycles and come with an extensive 10-year warranty, making them ideal for long-term industrial applications.

For customers seeking reliability and peace of mind, SpiderWay’s LFP batteries, powered by A-grade cells, deliver unmatched performance, durability, and energy efficiency.

Comments

Post a Comment